Quick-Coupling Systems

Change attachments efficiently and safely

- Manual or hydraulic locking

- Sideshift can be integrated

- Quick device change

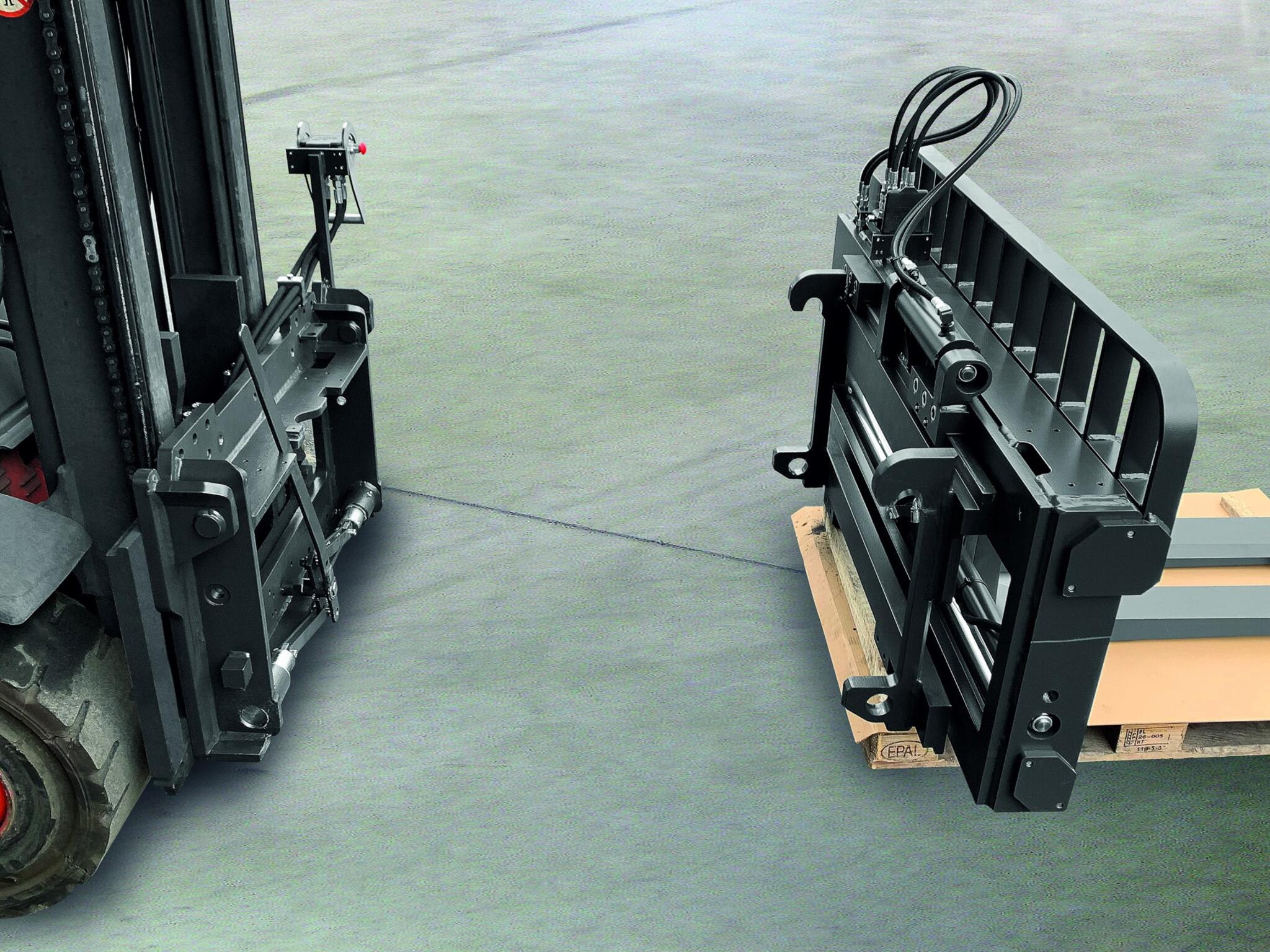

The quick-coupling system has been specially developed for forklift trucks with versatile applications and enables attachments to be changed quickly and without tools. Replacement is carried out using mounting hooks and manual or hydraulic locking via a cross bolt, whereby the hydraulic couplings between the forklift and the attachment must be connected manually.

For even greater convenience, an alternative version is available that offers fully automatic locking of the implement and the hydraulic couplings so that the driver can change the implement without having to dismount.

In addition, an integrated sideshift in the quick-coupling system ensures that all attached implements can be used flexibly and precisely - ideal for demanding applications that require a high degree of flexibility.

Quick-coupling system

Change attachments flexibly and quickly

A Quick-Coupling system is practical when switching between tasks frequently. In warehouses and logistics centres, attachments can be changed quickly without the driver having to dismount. This saves time and keeps the forklift truck in use for longer. The device is a valuable aid, especially when handling sensitive or bulky goods, as it is possible to switch to the appropriate attachment at any time.

Optional: Quick-Coupling system with Oil-Quick® locking system

he attachment is picked up with the Quick-Coupling system using the pick-up hook and then hydraulically locked via cross bolts. At the same time, the hydraulic circuits are connected fully automatically via the Oil-Quick® locking system. While the hydraulic lines always have to be connected manually with conventional Quick-Coupling systems, this process is completely eliminated with the Oil-Quick® locking system. With this technology, two separate additional hydraulic circuits can be made available to the attachments to be picked up. There is also the option of connecting an additional electric line and a leakage oil line.

Optional: sideshift and storage device

By fitting a sideshift to the Quick-Coupling system, this is available for every appliance picked up. The use of a parking device is recommended to ensure the quick and safe attachment of interchangeable devices.

The best solution with good advice.

We know that handling long, heavy and bulky loads presents users with special challenges. Arrange a no-obligation consultation with our specialists to find the best possible solution for your application.

Technical data

M - manual mechanical locking

H - hydraulic locking, 1 hydraulic function

| Modell | Load capacity | LC (LSP) | ISO | G | V | CoG (ESP) | Weight |

|---|---|---|---|---|---|---|---|

| S 25 - SCHWV 25-M | 2500 | 500 | 2 | 955 | 150 | 35 | 85 |

| S 25 - SCHWV 25-H | 2500 | 500 | 2 | 955 | 150 | 35 | 90 |

| S 25 - SCHWV 40-M | 4000 | 500 | 3 | 1055 | 165 | 40 | 130 |

| S 25 - SCHWV 40-H | 4000 | 500 | 3 | 1055 | 165 | 40 | 135 |

| S 25 - SCHWV 48-M | 5000 | 600 | 3 | 1055 | 170 | 40 | 145 |

| S 25 - SCHWV 48-H | 5000 | 600 | 3 | 1055 | 170 | 40 | 150 |

| S 25 - SCHWV 60-M | 6000 | 600 | 4 | 1170 | 205 | 60 | 250 |

| S 25 - SCHWV 60-H | 6000 | 600 | 4 | 1170 | 205 | 60 | 255 |

| S 25 - SCHWV 80-M | 8000 | 600 | 4 | 1170 | 215 | 60 | 270 |

| S 25 - SCHWV 80-H | 8000 | 600 | 4 | 1170 | 215 | 60 | 275 |

| S 25 - SCHWV 80/900-M ** | 8000 | 900 | 4 | 1170 | 215 | 60 | 290 |

| S 25 - SCHWV 80/900-H ** | 8000 | 900 | 4 | 1170 | 215 | 60 | 295 |

* With separate sideshift ± 100 mm (ISO 2 and 3) or ± 150 mm (ISO 4) (technical datas - on request)

** S 25-SCHWV 80-900-M and -H not available with separate sideshift

When carrying out fork handling, an additional fork carriage is required to mount the forks.

Surcharge for mounting hooks of the stabau attachments to be installed (depending on the type of attachment) on request

Surcharge for multiple quick-coupling system on request.

Parking devices for attachments on request

Standard values for residual load capacity of lift trucks**

| Quick Coupling System (Fork Carriage) | S 25 - | SCHWV 25 | SCHWV 25 | SCHWV 40 | SCHWV 40 | SCHWV 48 | SCHWV 48 | SCHWV 48/60 | SCHWV 60 | SCHWV 80 | SCHWV 80 | SCHWV 80/900 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load capacity lift truck | kg | 1500 | 2500 | 3000 | 4000 | 4500 | 5000/500 | 5000 | 6000 | 7000 | 8000 | 10000 |

| X* | mm | 350 | 450 | 450 | 500 | 500 | 500 | 560 | 560 | 650 | 650 | 750 |

| LC (LSP) = 500 mm | kg | 1140 | 1980 | 2310 | 3150 | 3525 | 3950 | |||||

| LC (LSP) = 600 mm | kg | 1040 | 1820 | 2125 | 2905 | 3255 | 3630 | 3790 | 4600 | 5340 | 6155 | 7750 |

| LC (LSP) = 800 mm | kg | 880 | 1565 | 1835 | 2520 | 2825 | 3155 | 3320 | 4040 | 4725 | 5450 | 6900 |

** The load capacity applies to lifting heights up to 3300 mm; specifications for greater lifting heights on request.

* Assumed dimensions

M - Manual locking system

H - hydraulic locking system, 1 hydraulic function

| Model | Load capacity | LC (LSP) | G | V | CoG (ESP) | Weight |

|---|---|---|---|---|---|---|

| kg | mm | mm | mm | mm | kg | |

| S 25 - SCHWVI 25-M | 2500 | 500 | 955 | 165 | 40 | 110 |

| S 25 - SCHWVI 25-H | 2500 | 500 | 955 | 165 | 40 | 115 |

| S 25 - SCHWVI 40-M | 4000 | 500 | 1055 | 180 | 50 | 160 |

| S 25 - SCHWVI 40-H | 4000 | 500 | 1055 | 180 | 50 | 165 |

| S 25 - SCHWVI 48-M | 5000 | 600 | 1055 | 185 | 50 | 175 |

| S 25 - SCHWVI 48-H | 5000 | 600 | 1055 | 185 | 50 | 180 |

| S 25 - SCHWVI 60-M | 6000 | 600 | 1170 | 210 | 60 | 255 |

| S 25 - SCHWVI 60-H | 6000 | 600 | 1170 | 210 | 60 | 260 |

| S 25 - SCHWVI 80-M | 8000 | 600 | 1170 | 215 | 60 | 295 |

| S 25 - SCHWVI 80-H | 8000 | 600 | 1170 | 215 | 60 | 300 |

| S 25 - SCHWVI 80/900-H | 8000 | 900 | 1170 | 220 | 60 | 315 |

| S 25 - SCHWVI 80/900-H | 8000 | 900 | 1170 | 220 | 60 | 320 |

* With separate sideshift ± 100 mm up to SCHWVI 48, SCHWVI 60 and larger with ± 150 mm sideshift

When carrying out fork handling, an additional fork carriage is required to mount forks.

Lost load center, center of gravity and weight from front edge of side brackets.

Design includes side brackets.

Detail drawings of fork carriage, roller studs and chain anchors or the fork carriage have to be provided by the customer.

Surcharge for mounting hooks of the stabau attachments to be installed (depending on the type of attachment) on request

Surcharge for multiple hydraulic coupling system on request.

Parking devices for attachments on request