Telescopic forks

Increase reach

- Forced synchronisationfor high precision

- Ideal for lorry loadingand double-depth storage

- 1- or 2-cylinder version

Telescopic forks are used in many areas of logistics and warehouse technology to enable one-sided lorry loading and unloading or storage in double racking. The forks can also be used as extension forks to adjust the load depth. The telescopic forks are equipped with forced synchronisation in single and double-cylinder versions. Compared to reach forks and feed fork carriers, the residual load capacity values of the forklift truck and the visibility conditions are more favourable.

Telescopic forks

Quality and flexibility for the highest demands

stabau telescopic forks are an innovative solution for the precise and safe handling of loads. Our telescopic forks ensure efficiency in many different areas of application and are characterised by durable quality and reliable performance.

stabau telescopic forks - Precise control and effortless operation

With stabau telescopic forks, you get a tool that allows loads to be extended and retracted with precision. The hydraulic control system enables smooth and controlled movement of the forks so that you can get the job done efficiently and safely.

Optional features

Getting the most out of the telescopic forks

Wear-resistant manganese strips available below the outer fork, dimension S increases by 5 mm.

Pallet Stops Type A1:

Move next to the fork back when the forks are retracted. Price A 1 (90 mm high, 50 mm wide)

Pallet Stops Type A2:

Are used to limit the fork length to the desired usable fork length.

Minimum distance to the fork back is 75 mm.

400 mm high

Pallet Stops Type A3:

Are used to limit the fork length to the desired usable fork length.

High pallet stop A3 supports the load.

Minimum distance to the fork back is 125 mm.

850 mm high (reinforced)

Load Backrest Typ LG:

Is mounted on pallet stop A 2 (supplied with the product) and moves

forward together with the outer forks. Forks are adjustable within the

backrest width.

Minimum distance to the fork back is 100 mm.

Width: 750 mm Height: 1200 mm

- Bolt-on telescopic forks, e.g. for tine adjustment

- Camera systems

- Cold storage version

- Explosion-proof design

- Higher load capacities and other cross-sections

- Stroke max. 1200mm, fork length max. 2000mm

- Fork adjustment with telescopic forks

The best solution with good advice.

We know that handling long, heavy and bulky loads presents users with special challenges. Arrange a no-obligation consultation with our specialists to find the best possible solution for your application.

Technical data

Telescopic forks (for retracting and extending with load)

1 Hydraulic function

Integrated synchronisation up to and including TGH 60

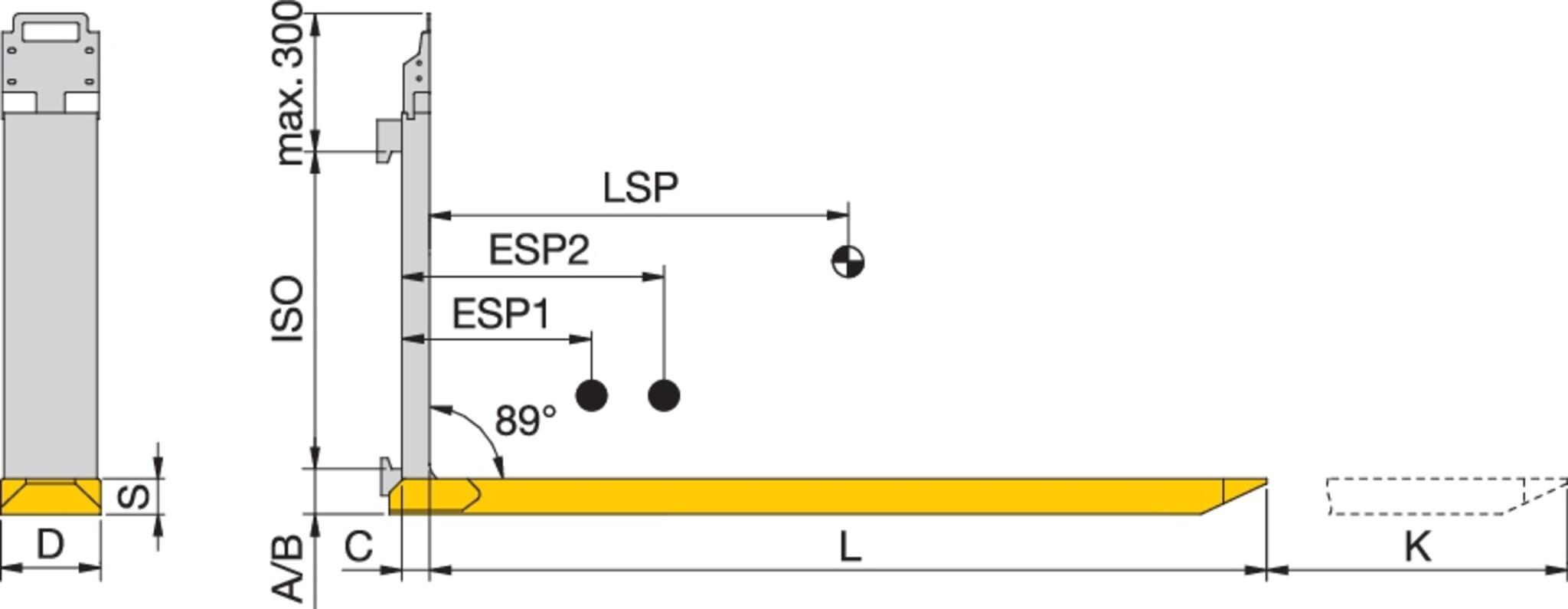

| Model | Load capacity in kg | for lift trucks up to | ISO | Cross section* DxS | C | L | K | CoG 1/ CoG 2 ESP 1/ ESP 2 | Weight per pair | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 600 | 1450 | 1750 | ||||||||||

| mm | mm | mm | to | mm | mm | mm | mm | mm | mm | kg | ||

| 1-Zylinder-Ausführung | ||||||||||||

| S 5 - TGHS 20 1200/850 | 2000 | 960 | 800 | 2,0/600 | 2 | 133x58 | 45 | 1200 | 850 | 420/625 | 160 | |

| S 5 - TGHS 20 1350/1000 | 1350 | 1000 | 490/735 | 175 | ||||||||

| S 5 - TGHS 25 1200/850 | 2500 | 1450 | 1200 | 2,5/600 | 2 | 133x63 | 50 | 1200 | 850 | 425/610 | 175 | |

| S 5 - TGHS 25 1350/1000 | 1350 | 1000 | 495/720 | 195 | ||||||||

| S 5 - TGHS 30 1200/850 | 3000 | 1450 | 1200 | 3,0/500 | 3 | 133x63 | 50 | 1200 | 850 | 405/585 | 185 | |

| S 5 - TGHS 30 1350/1000 | 1350 | 1000 | 475/690 | 200 | ||||||||

| 2-Zylinder-Ausführung | ||||||||||||

| S 5 - TGH 25 1200/850 | 2500 | 1450 | 1200 | 2,5/600 | 2 | 163x58 | 45 | 1200 | 850 | 415/625 | 195 | |

| S 5 - TGH 25 1350/1000 | 1350 | 1000 | 485/740 | 210 | ||||||||

| S 5 - TGH 30 1200/850 | 3000 | 1450 | 1200 | 3,0/500 | 3 | 163x58 | 45 | 1200 | 850 | 400/600 | 205 | |

| S 5 - TGH 30 1350/1000 | 1350 | 1000 | 465/710 | 220 | ||||||||

| S 5 - TGH 40 1200/850 | 4000 | 1850 | 1550 | 3,5/600 4,0/500 | 3 | 163x58 | 45 | 1200 | 850 | 400/600 | 205 | |

| S 5 - TGH 40 1350/1000 | 1350 | 1000 | 465/710 | 220 | ||||||||

| S 5 - TGH 48 1200/850 | 5000 | 2310 | 1920 | 5,0/600 | 3 | 165x64 | 50 | 1200 | 850 | 405/605 | 230 | |

| S 5 - TGH 48 1350/1000 | 1350 | 1000 | 475/715 | 250 | ||||||||

| S 5 - TGH 50 1200/850 | 5000 | 2310 | 1920 | 5,0/600 | 4 | 165x64 | 50 | 1200 | 850 | 370/550 | 255 | |

| S 5 - TGH 50 1350/1000 | 1350 | 1000 | 430/655 | 275 | ||||||||

| S 5 - TGH 60 1200/850 | 6000 | 3100 | 2560 | 6,0/600 | 4 | 217x67 | 50 | 1200 | 850 | 380/570 | 350 | |

| S 5 - TGH 60 1350/1000 | 1350 | 1000 | 445/680 | 380 | ||||||||

| S 5 - TGH 80 1200/850 | 8000 | 4300 | 3600 | 8,0/600 | 4 | 217x77 | 60 | 1200 | 850 | 380/550 | 415 | |

| S 5 - TGH 80 1350/1000 | 1350 | 1000 | 445/650 | 450 | ||||||||

One-sided loading and unloading of trucks requires a usable length of 1350 mm with a stroke of 1000 mm.

* Fork shoe reinforced in the rear area (10 mm wider)

* Wear-resistant manganese strips are available below the outer fork, dimension S increases by 5 mm - available as an option

Stops A 1 (each side of the fork back) or A 2 (400 mm high) or stops A 3 (reinforced and 850 mm high) - available as an option

Load backrests (width 750 mm, height 1200 mm) incl. A 2 stops - available as an option

Screwed telescopic forks e.g. for fork positoner - available as an option

Camera systems - available as an option

Cold store version - on request

Ex-protection Version - on request

Higher capacities and other cross sections on request.

Stroke max. 1200 mm, fork length max. 2000 mm

Fork positioner with telescopic forks also available

Guide values for the residual load capacity of forklifts **

| Telescopic Forks | S 5 - | TGHS 20 | TGHS 20 | TGH 25 TGHS 25 | TGH 30 TGHS 30 | TGH 40 | TGH 40 | TGH 48 | TGH 48 | TGH 48 TGH 50 | TGH 60 | TGH 80 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load capacity lift truck | kg/mm | 1800/500 | 2000/500 | 2500/500 | 3000/500 | 3500/500 | 4000/500 | 4500/500 | 5000/500 | 5000/600 | 6000/600 | 8000/600 |

| X* | mm | 400 | 450 | 450 | 450 | 500 | 500 | 500 | 500 | 560 | 560 | 650 |

| LC (LSP) = 600 mm | kg | 1570 | 1720 | 2170 | 2620 | 3130 | 3550 | 4000 | 4540 | 4940 | 5950 | 7900 |

| LC (LSP)= 750 mm | kg | 1360 | 1510 | 1900 | 2300 | 2760 | 3120 | 3520 | 3950 | 4370 | 5260 | 7050 |

| LC (LSP)= 1200 mm | kg | 940 | 1050 | 1330 | 1620 | 1980 | 2250 | 2530 | 2800¹ | 2800¹ | 3830 | 5250¹ |

| LC (LSP)= 1450 mm | kg | 810 | 910 | 1160 | 1410 | 1720 | 1850¹ | 2210 | 2310¹ | 2310¹ | 3200¹ | 4300¹ |

| LC (LSP)= 1750 mm | kg | 700 | 790 | 1000 | 1200 | 1500 | 1550¹ | 1910 | 1920¹ | 1920¹ | 2650¹ | 3600¹ |

** The load capacity applies to lifting heights up to 3300 mm; Specifications for greater lifting heights on request.

* Assumed dimensions

¹ Load capacity of lift truck may be higher

Hydraulically Adjustable Fork Extensions (retractable and extendable without load)

1 Hydraulic function

| Model | Load capacity per pair | LC (LSP) | for lift trucks up to | ISO | L | K | Cross section D x S* | C | CoG 1/ CoG 2 (ESP 1)/ (ESP 2) | Weight/ pair | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | mm | to | mm | mm | mm | mm | mm | mm | kg | ||

| S 5 - VGH 20 800/400 | 2000 | 600 | 2,0 | 2 | 800 | 400 | 133 | 58 | 45 | 245/330 | 120 |

| S 5 - VGH 20 1200/400 | 1200 | 400 | 425/520 | 165 | |||||||

| S 5 - VGH 25 800/400 | 2500 | 600 | 2,5 | 2 | 800 | 400 | 163 | 58 | 45 | 245/330 | 145 |

| S 5 - VGH 25 1200/400 | 1200 | 400 | 425/520 | 205 | |||||||

| S 5 - VGH 35 800/400 | 3500 | 600 | 3,5 | 3 | 800 | 400 | 163 | 58 | 45 | 230/310 | 155 |

| S 5 - VGH 35 1200/400 | 1200 | 400 | 405/495 | 215 | |||||||

Surcharge for wear resistant manganese steel strips on underside of outer forks (5 mm thick) - on request

* Fork shoe reinforced in the rear area (10 mm wider)

* When using wear resistant strips of manganese steel, dimension S increases by 5 mm.

Load Extenders

1 hydraulic function

| Model | Load capacity* | LC (LSP) | ISO | B | G | H*** | K | V | V** | CoG 1 / CoG 2 (ESP 1) / (ESP 2) | CoG 1** / CoG 2 (ESP 1*) / (ESP 2) | Weight | Weight** |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | kg | ||

| S 5 - VSCHGT 10 | 1000 | 600 | 2 | 1000 | 750 | 900 | 950 | 315 | 365 | 150/630 | 180/570 | 325 | 375 |

| S 5 - VSCHGT 15 | 1500 | 600 | 2 | 1000 | 750 | 900 | 950 | 330 | 380 | 160/650 | 185/590 | 360 | 410 |

| S 5 - VSCHGT 25 | 2500 | 600 | 3 | 1000 | 750 | 900 | 950 | 380 | 440 | 185/695 | 220/665 | 470 | 535 |

* Load capacity of retracted attachment

** with integrated sideshifter ± 100 mm

*** For ISO A-mounting

Surcharge for forks, on request

Load extenders can be used as load pushers. The forks are mounted on the fork carriage of the lift truck, so that the load can be pushed off forward.

Standard values for residual load capacity of lift trucks**

| Model | Load capacity* | LC (LSP) | ISO | B | G | H*** | K | V | V** | CoG 1 / CoG 2 (ESP 1) / (ESP 2) | CoG 1** / CoG 2 (ESP 1*) / (ESP 2) | Weight | Weight** |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | kg | ||

| S 5 - VSCHGT 10 | 1000 | 600 | 2 | 1000 | 750 | 900 | 950 | 315 | 365 | 150/630 | 180/570 | 325 | 375 |

| S 5 - VSCHGT 15 | 1500 | 600 | 2 | 1000 | 750 | 900 | 950 | 330 | 380 | 160/650 | 185/590 | 360 | 410 |

| S 5 - VSCHGT 25 | 2500 | 600 | 3 | 1000 | 750 | 900 | 950 | 380 | 440 | 185/695 | 220/665 | 470 | 535 |

** Die Tragfähigkeit gilt für Hubhöhen bis 3300 mm; Richtwerte für größere Hubhöhen bitte anfragen.

* Angenommenes Maß