Fork Clamps

Fixed and rotatable versions

- For palletlesstransportation

- Optionally withrotating function

- Advantage for residual load capacity

The fork clamp allows the forks to be adjusted across the width of the forklift truck. Thanks to the robust design and corresponding cylinders with non-return valves, high clamping forces can be generated and maintained between the forks.

A rotating fork clamp can also be used to pick up various containers and empty them sideways.

Technical data

In order to keep maintenance costs low, we recommend using bolt-on forks.

Forks serially welded on

1 Hydraulic function

| Model | Load capacity Clamping function | Load capacity Fork function | LSP | ISO | Omin- Omax IK-IK | G | D | S | L | V | ESP | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | kg | mm | mm | mm | mm | mm | mm | mm | mm | kg | ||

| S 12-KG 15 | 1500 | 1800 | 500 | 2 | 300-1360 | 950 | 120 | 40 | 1200 | 130 | 200 | 370 |

| S 12-KG 22 | 2200 | 2500 | 500 | 2 | 300-1460 | 1050 | 125 | 45 | 1200 | 130 | 215 | 400 |

| S 12-KG 28 | 2800 | 3300 | 500 | 3 | 280-1550 | 1150 | 140 | 50 | 1200 | 140 | 210 | 540 |

| S 12-KG 35 | 3500 | 4000 | 500 | 3 | 280-1650 | 1250 | 140 | 50 | 1200 | 140 | 205 | 555 |

| S 12-KG 45 | 4500 | 5000 | 500 | 3 | 260-1700 | 1350 | 150 | 60 | 1200 | 155 | 215 | 695 |

| S 12-KG 48 | 4500 | 5000 | 600 | 3 | 260-1700 | 1350 | 150 | 60 | 1200 | 155 | 210 | 710 |

| S 12-KG 50 | 5000 | 6000 | 600 | 4 | 260-1800 | 1450 | 150 | 65 | 1200 | 155 | 215 | 800 |

| S 12-KG 60 | 6000 | 7000 | 600 | 4 | 260-1950 | 1600 | 150 | 70 | 1200 | 175 | 200 | 1005 |

| S 12-KG 70 | 7000 | 8000 | 600 | 4 | 260-2100 | 1750 | 200 | 70 | 1200 | 175 | 215 | 1230 |

| S 12-KG 80 | 7200 | 10000 | 600 | 4 | 260-2100 | 2000 | 200 | 80 | 1200 | 175 | 220 | 1375 |

Bolt-on forks on request

Adjustable pressure relief valve on request

Pressure gauge on request

Bumpers in front of the connections of the adjusting cylinders on request

Integral design on request

Fork lengths from 1.600 mm on request

Standard values for residual load capacity of lift trucks**

| Fork Clamps | S 12 - | KG 15 | KG 22 | KG 22 | KG 28 | KG 35 | KG 35 | KG 45 | KG 45 | KG 48/50 | KG 50 | KG 60 | KG 60 | KG 70 | KG 70 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load capacity | kg | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000/500 | 5000 | 6000 | 6000 | 7000 | 7000 | 8000 |

| X* | mm | 350 | 450 | 450 | 450 | 500 | 500 | 500 | 500 | 560 | 560 | 560 | 650 | 650 | 650 |

| LC (LSP) = 500 mm | kg | 1180 | 1620 | 2070 | 2410 | 2880 | 3320 | 3600 | 4090 | ||||||

| LC (LSP) = 600 mm | kg | 1070 | 1480 | 1900 | 2210 | 2650 | 3050 | 3310 | 3770 | 4150 | 5030 | 4840 | 5830 | 5700 | 6580 |

| LC (LSP) = 700 mm | kg | 980 | 1370 | (1730) | 2040 | 2450 | (2750) | 3070 | 3490 | 3860 | 4680 | 4510 | 5450 | 5330 | 6190 |

| LC (LSP) = 800 mm | kg | 900 | 1270 | (1510) | 1890 | 2280 | (2400) | 2860 | (3100) | 3610 | (4130) | 4210 | (4950) | 5000 | 5770 |

** The load capacity applies to lifting heights up to 3300 mm; specifications for greater lifting heights on request.

* Assumed dimensions

For greater load centers, where the lift truck has a higher residual load capacity than the attachment, those values, upon the exceedance of which the attachment would be overloaded, are indicated in brackets ( ).

Fork Clamps with Separate Sideshift

2 Hydraulic functions

In order to keep maintenance costs low, we recommend using bolt-on forks.

Forks serially welded on

| Model | Load capacity Clamping function | Load capacity Fork function | LSP | ISO | Omin- Omax IK-IK | G | Side- shift | D | S | L | V | ESP | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | kg | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | ||

| S 12-KG 15-S | 1500 | 1800 | 500 | 2 | 300-1360 | 950 | ± 100 | 120 | 40 | 1200 | 145 | 200 | 400 |

| S 12-KG 22-S | 2200 | 2500 | 500 | 2 | 300-1460 | 1050 | ± 100 | 125 | 45 | 1200 | 145 | 215 | 430 |

| S 12-KG 28-S | 2800 | 3300 | 500 | 3 | 280-1550 | 1150 | ± 100 | 140 | 50 | 1200 | 155 | 210 | 580 |

| S 12-KG 35-S | 3500 | 4000 | 500 | 3 | 280-1650 | 1250 | ± 100 | 140 | 50 | 1200 | 155 | 205 | 595 |

| S 12-KG 45-S | 4500 | 5000 | 500 | 3 | 260-1700 | 1350 | ± 100 | 150 | 60 | 1200 | 170 | 220 | 735 |

| S 12-KG 48-S | 4500 | 5000 | 600 | 3 | 260-1700 | 1350 | ± 100 | 150 | 60 | 1200 | 170 | 215 | 750 |

| S 12-KG 50-S | 5000 | 6000 | 600 | 4 | 260-1800 | 1450 | ± 100 | 150 | 65 | 1200 | 170 | 215 | 860 |

| S 12-KG 60-S | 6000 | 7000 | 600 | 4 | 260-1950 | 1600 | ± 150 | 150 | 70 | 1200 | 195 | 205 | 1085 |

| S 12-KG 70-S | 7000 | 8000 | 600 | 4 | 260-2100 | 1750 | ± 150 | 200 | 70 | 1200 | 195 | 220 | 1310 |

| S 12-KG 80-S | 7200 | 10000 | 600 | 4 | 260-2100 | 2000 | ± 150 | 200 | 80 | 1200 | 195 | 225 | 1455 |

Bolt-on forks on request

Adjustable pressure relief valve on request

Pressure gauge on request

Bumpers in front of the connections of the adjusting cylinders on request

Integral design on request

Fork lengths from 1.600 mm on request

Standard values for residual load capacity of lift trucks**

| Fork Clamps | S 12 - | KG 15-S | KG 22-S | KG 22-S | KG 28-S | KG 35-S | KG 35-S | KG 45-S | KG 45-S | KG 48/50-S | KG 50-S | KG 60-S | KG 60-S | KG 70-S | KG 70-S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load capacity lift truck | kg | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000/500 | 5000 | 6000 | 6000 | 7000 | 7000 | 8000 |

| X* | mm | 350 | 450 | 450 | 450 | 500 | 500 | 500 | 500 | 560 | 560 | 560 | 650 | 650 | 650 |

| LC (LSP) = 500 mm | kg | 1140 | 1580 | 2020 | 2350 | 2810 | 3250 | 3530 | 4010 | ||||||

| LC (LSP) = 600 mm | kg | 1040 | 1450 | 1850 | 2150 | 2600 | 3000 | 3250 | 3700 | 4070 | 4930 | 4720 | 5700 | 5580 | 6440 |

| LC (LSP) = 700 mm | kg | 950 | 1340 | 1700 | 1990 | 2400 | 2770 | 3020 | 3430 | 3780 | 4600 | 4400 | 5340 | 5220 | 6030 |

| LC (LSP) = 800 mm | kg | 880 | 1240 | (1510) | 1850 | 2230 | (2410) | 2810 | (3100) | 3540 | (4130) | 4120 | (4950) | 4900 | 5660 |

** The load capacity applies to lifting heights up to 3300 mm; specifications for greater lifting heights on request.

* Assumed dimensions

For greater load centers, where the lift truck has a higher residual load capacity than the attachment, those values, upon the exceedance of which the attachment would be overloaded, are indicated in brackets ( ).

Fork Clamps, Rotatable

2 Hydraulic functions

In order to keep maintenance costs low, we recommend using bolt-on forks.

Forks serially welded on - Rotation range 360°

| Model | Load capacity clamping function | LSP | ISO | Omin- Omax IK-IK | G | D | S | L | V | ESP | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | mm | mm | mm | mm | mm | mm | mm | mm | kg | ||

| S 12-KG 15-360° | 1500 | 500 | 2 | 300-1360 | 950 | 120 | 40 | 1200 | 250 | 225 | 595 |

| S 12-KG 22-360° | 2200 | 500 | 2 | 300-1460 | 1050 | 125 | 45 | 1200 | 250 | 235 | 635 |

| S 12-KG 28-360° | 2800 | 500 | 3 | 280-1550 | 1150 | 140 | 50 | 1200 | 265 | 245 | 810 |

| S 12-KG 35-360° | 3500 | 500 | 3 | 280-1650 | 1250 | 140 | 50 | 1200 | 275 | 245 | 880 |

| S 12-KG 40-360° | 4000 | 600 | 3 | 260-1700 | 1350 | 150 | 60 | 1200 | 290 | 265 | 1015 |

| S 12-KG 45-360° | 4500 | 600 | 4 | 260-1700 | 1350 | 150 | 60 | 1200 | 295 | 240 | 1235 |

| S 12-KG 50-360° | 5000 | 600 | 4 | 260-1800 | 1450 | 150 | 65 | 1200 | 295 | 250 | 1290 |

| S 12-KG 60-360° | 6000 | 600 | 4 | 260-1950 | 1600 | 150 | 70 | 1200 | 310 | 255 | 1550 |

| S 12-KG 70-360° | 7000 | 600 | 4 | 260-2100 | 1750 | 200 | 70 | 1200 | 335 | 280 | 1885 |

| S 12-KG 80-360° | 7200 | 600 | 4 | 260-2100 | 2000 | 200 | 80 | 1200 | 335 | 285 | 2030 |

Bolt-on forks on request

Adjustable pressure relief valve on request

Pressure gauge on request

Solenoid valve for separate Sideshift incl. hydraulic safety bar - on request

(utilzation for only rotation/sideshift admissible)

Bumpers in front of the connections of the adjusting cylinders on request

Integral design - on request

Fork lengths from 1.600 mm on request

Standard values for residual load capacity of lift trucks**

| Fork Clamps | S 12 - | KG 15 -360° | KG 15 -360° | KG 22 -360° | KG 28 -360° | KG 28 -360° | KG 35 -360° | KG 35 -360° | KG 40 -360° | KG 45 -360° | KG 50 -360° | KG 60 -360° | KG 70 -360° |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load capacity lift truck | kg | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000/500 | 5000 | 6000 | 7000 | 8000 |

| X* | mm | 350 | 450 | 450 | 450 | 500 | 500 | 500 | 500 | 560 | 560 | 650 | 650 |

| LC (LSP) = 500 mm | kg | 940 | 1360 | 1730 | 2000 | 2440 | 2780 | 3180 | 3470 | ||||

| LC (LSP) = 600 mm | kg | 860 | 1260 | 1600 | 1850 | 2260 | 2580 | 2940 | 3220 | 3520 | 4260 | 4980 | 5520 |

| LC (LSP) = 700 mm | kg | 800 | 1170 | 1480 | 1720 | 2110 | 2400 | 2740 | 3000 | 3300 | 3990 | 4680 | 5200 |

| LC (LSP) = 800 mm | kg | 740 | (1030) | 1390 | 1610 | (1930) | 2250 | (2410) | 2810 | 3100 | 3750 | 4410 | 4900 |

** The load capacity applies to lifting heights up to 3300 mm; specifications for greater lifting heights on request.

* Assumed dimensions

For greater load centers, where the lift truck has a higher residual load capacity than the attachment, those values, upon the exceedance of which the attachment would be overloaded, are indicated in brackets ( ).

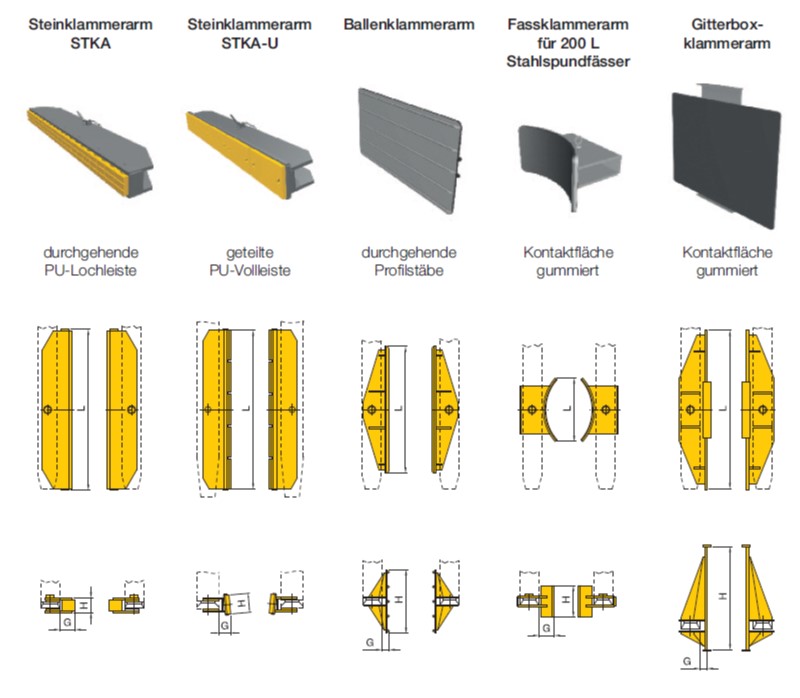

| Model | Load capacity | L | H | G | Weight per pair |

|---|---|---|---|---|---|

| kg | mm | mm | mm | kg | |

| S 12-STKA 20 | 2000 | 1200 | 94 | 95 | 120 |

| S 12-STKA 20-U | 2000 | 1200 | 120 | 75 | 120 |

| S 12-BKA 20 | 2000 | 800 | 400 | 40 | 120 |

| S 12-FKA 20 | 2000 | 400 | 200 | 100 | 40 |

| S 12 - GBA 20 | 2000 | 1240 | 900 | 35 | 190 |

Tilting clamp arms and special designs on request.

The best solution with good advice.

We know that handling long, heavy and bulky loads presents users with special challenges. Arrange a no-obligation consultation with our specialists to find the best possible solution for your application.